Manufacturing Capability

Manufacturing Capability

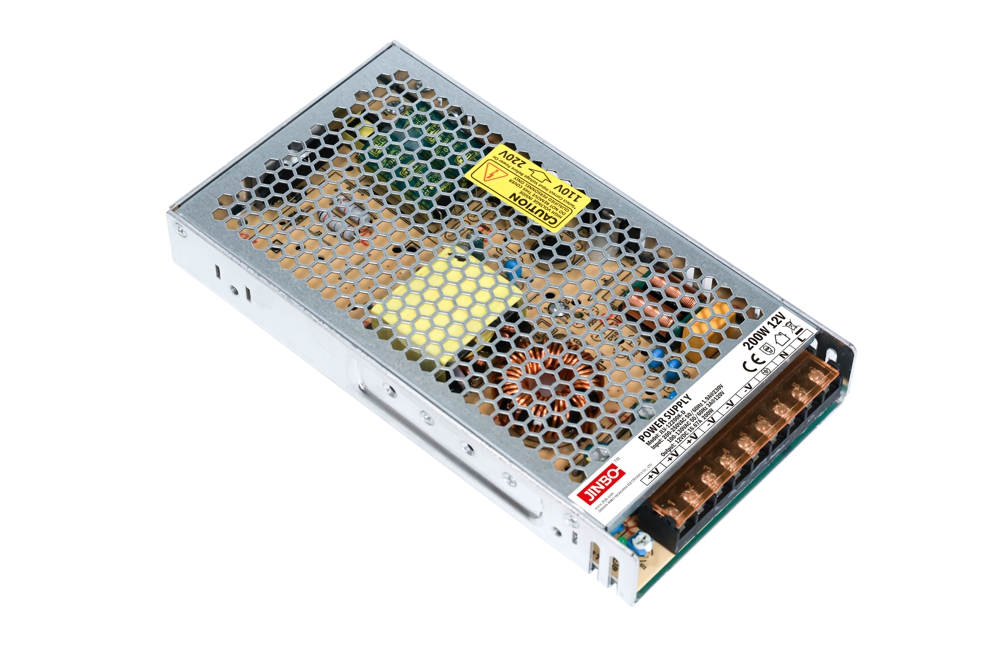

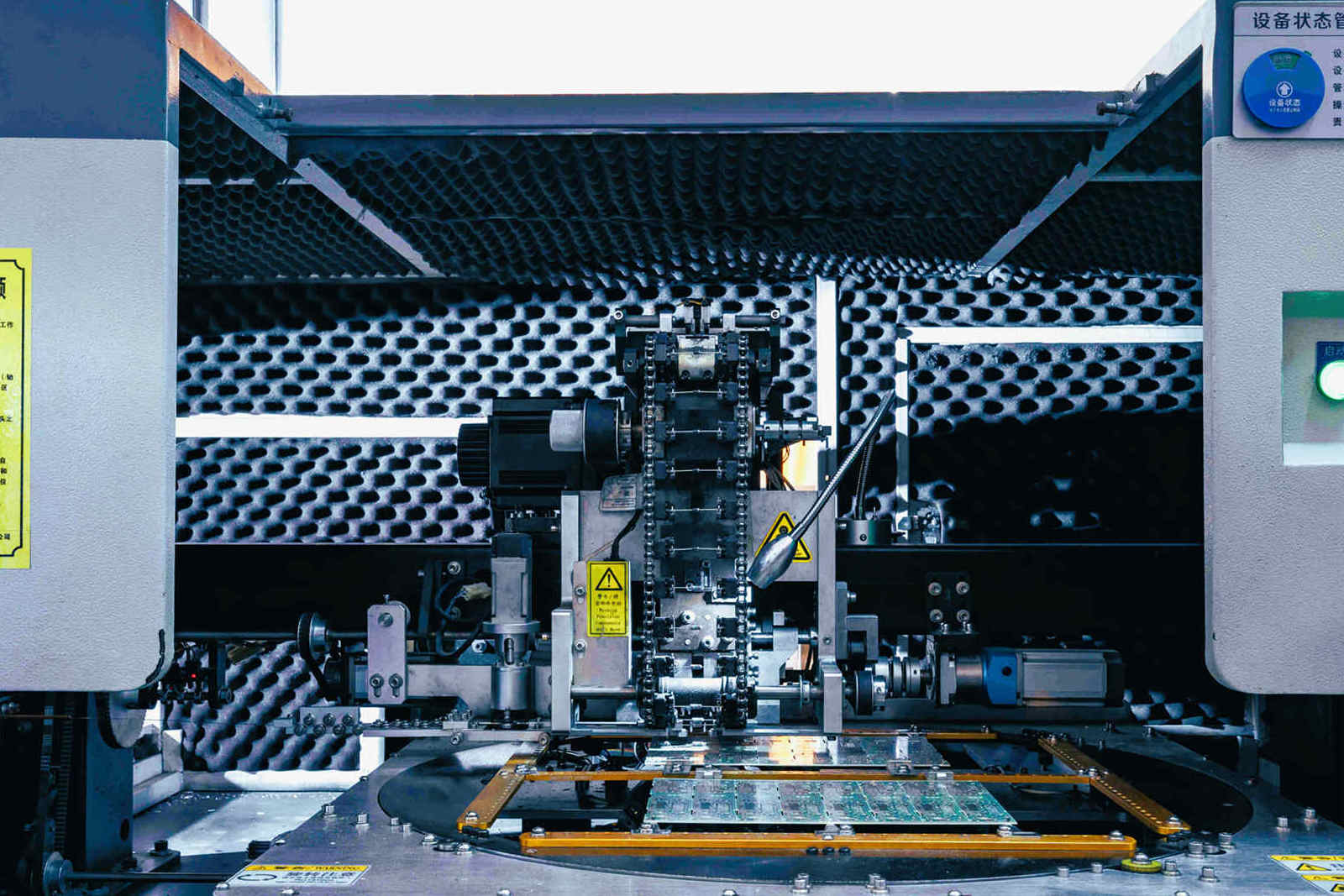

Our manufacturing operation combines advanced automation, skilled personnel, and mature production management to deliver reliable power supply solutions at scale. With five complete production lines supported by four SMT production lines and four automatic insertion machines, we are able to maintain consistent quality while responding efficiently to diverse market requirements and customer projects.

Product reliability is reinforced through a comprehensive testing and finishing process. Eight automated aging and burn-in test systems ensure that every power supply is verified under load before shipment. Robot-assisted potting machines are used for sealed and waterproof products, improving consistency and durability. Final processing is completed through three packaging lines and four laser marking machines, ensuring clear identification, traceability, and a professional finished product.

Supported by a dedicated workforce of more than 300 employees, our factory achieves an annual output of approximately 10 million pieces of SMPS products and related accessories. This manufacturing strength allows us to support long-term partnerships, stable supply, and OEM and ODM cooperation, while continuously delivering products that meet performance, reliability, and market expectations.

In-Line Inspection & Process Control

To prevent defects before they propagate, in-line inspection systems monitor each stage of production:

AOI (Automated Optical Inspection) checks component placement, polarity, and solder quality

Process monitoring tracks key parameters to ensure repeatability across batches

Traceable production records support quality audits and certification requirements

This closed-loop control allows early correction and reduces variability between production runs.

From the first schematic to final prototyping,

We prioritize three non-negotiables:

Stability

Optimized electrical architectures that resist voltage fluctuations and load shifts.

Efficiency

Thermal management and circuit design that minimize energy waste (and long-term operating costs).

Durability

Mechanical structures engineered to withstand continuous, 24/7 operation (no premature failures, no downtime).

Automated Testing for Electrical Performance

Every unit undergoes automated functional and electrical testing, verifying:

Output voltage and current stability

Load and protection behavior

Start-up and operational consistency

Automation ensures identical test conditions for every product—whether a small batch or high-volume order.

Built for Scale, Ready for Customization

Automated production allows us to balance efficiency and flexibility:

Stable quality from pilot runs to mass production

Fast transition from specification to manufacturing

Reliable execution of custom configurations and regional variants

The result is manufacturing that supports global standards, demanding applications, and long product lifecycles.

What This Means for Our Customers

Consistent quality across all production volumes

Reduced defect rates and improved long-term reliability

Predictable lead times and scalable supply

Confidence in compliance-driven markets

Automation is not just about speed—it is about control, consistency, and confidence in every power supply we deliver.