Wrong menu selected

- Home

- About us

- Products

Browse By Category

UL Listed Models

Controllers & Accessories

- Technology

- Support

- News

- Contact Us

Quality, since 1993

Info

Contact Us

- Tel: +86-756-2256343

- Fax: +86-756-2256723

- E-mail: info@zhjb.com

- Post Code: 519090

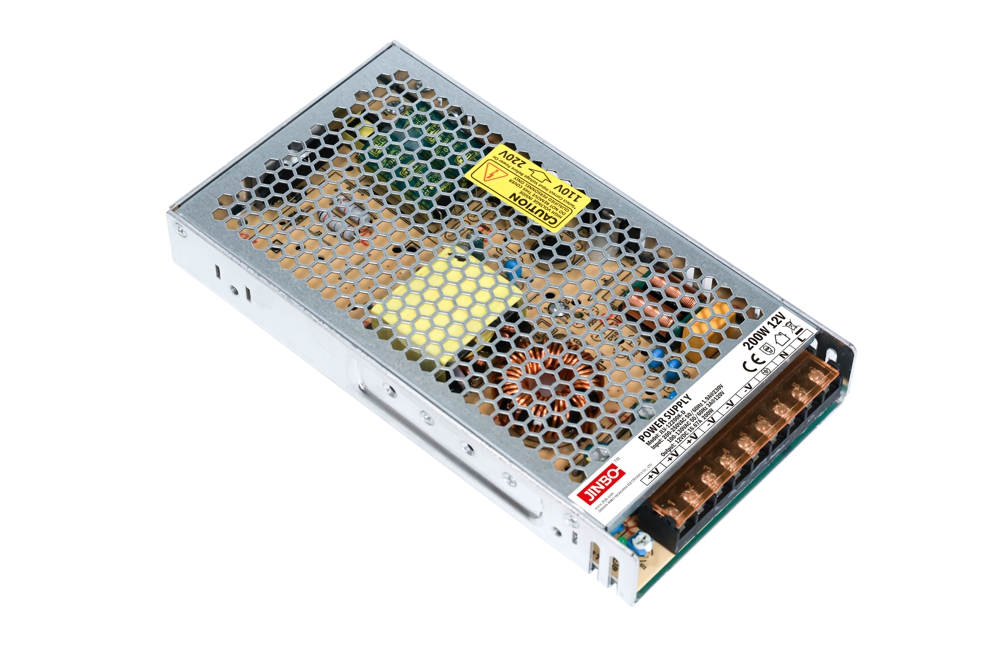

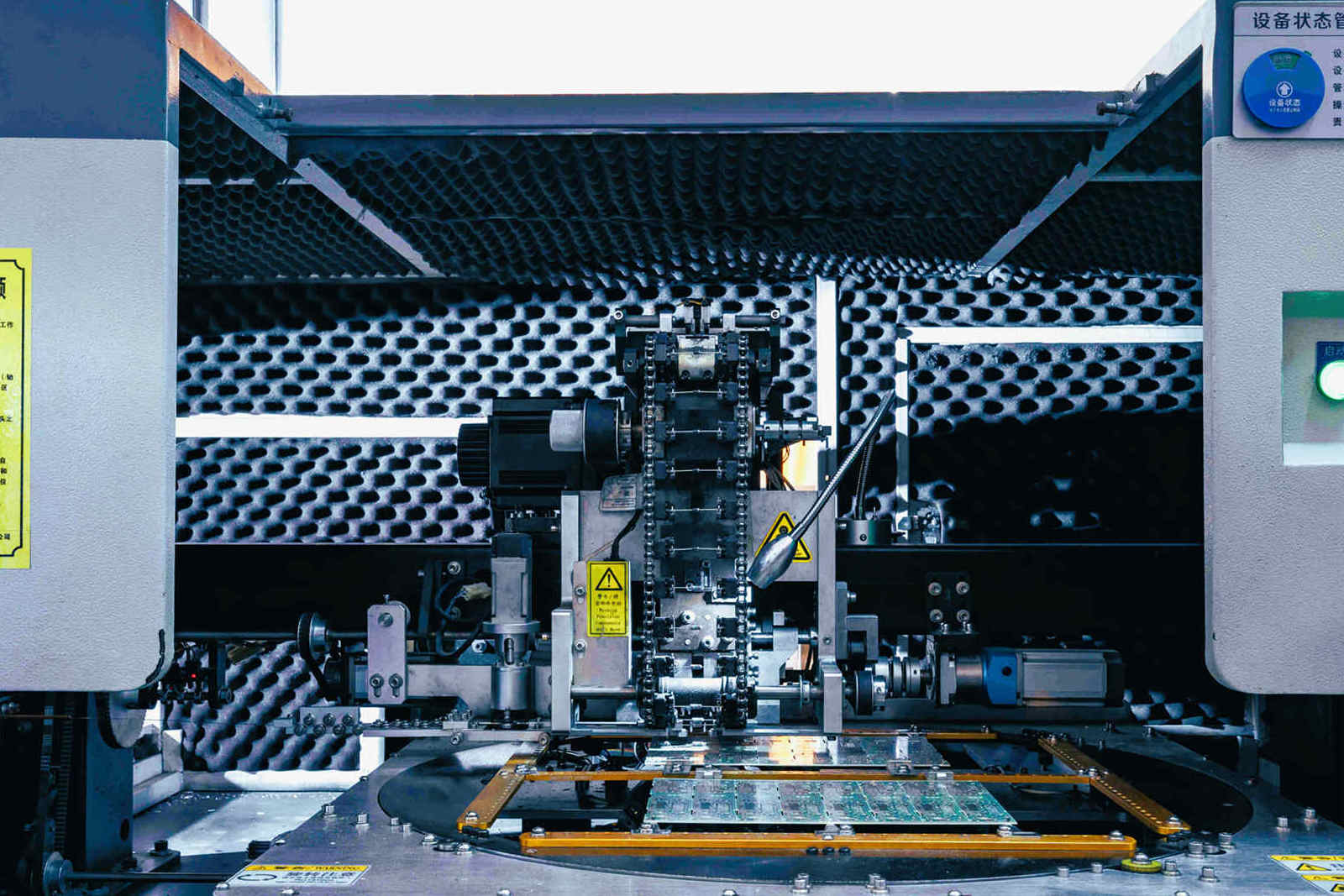

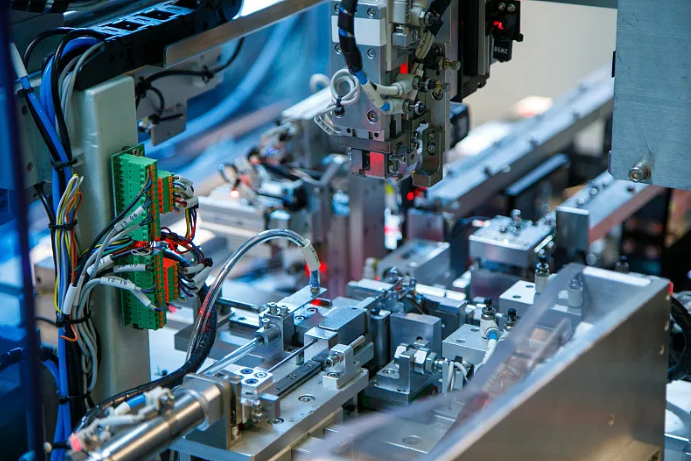

Products Range: LED Power Supply, LED Driver, LED Controller, Power Supply, Switching Power Supply, SMPS, LED Materials, Neon Transformer, Neon Materials

@2026 all rights reserved